Since there is no bulk melting of the. Heat is generated by friction between the rotating tool and the work piece material which leads to a softened region near the FSW tool.

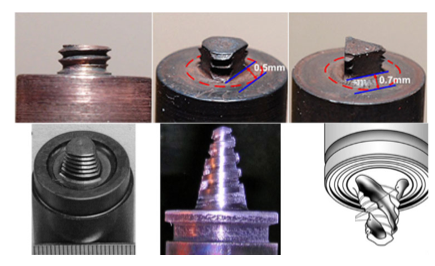

Friction Stir Welding Tools With Different Pin Profiles All Dimensions Download Scientific Diagram

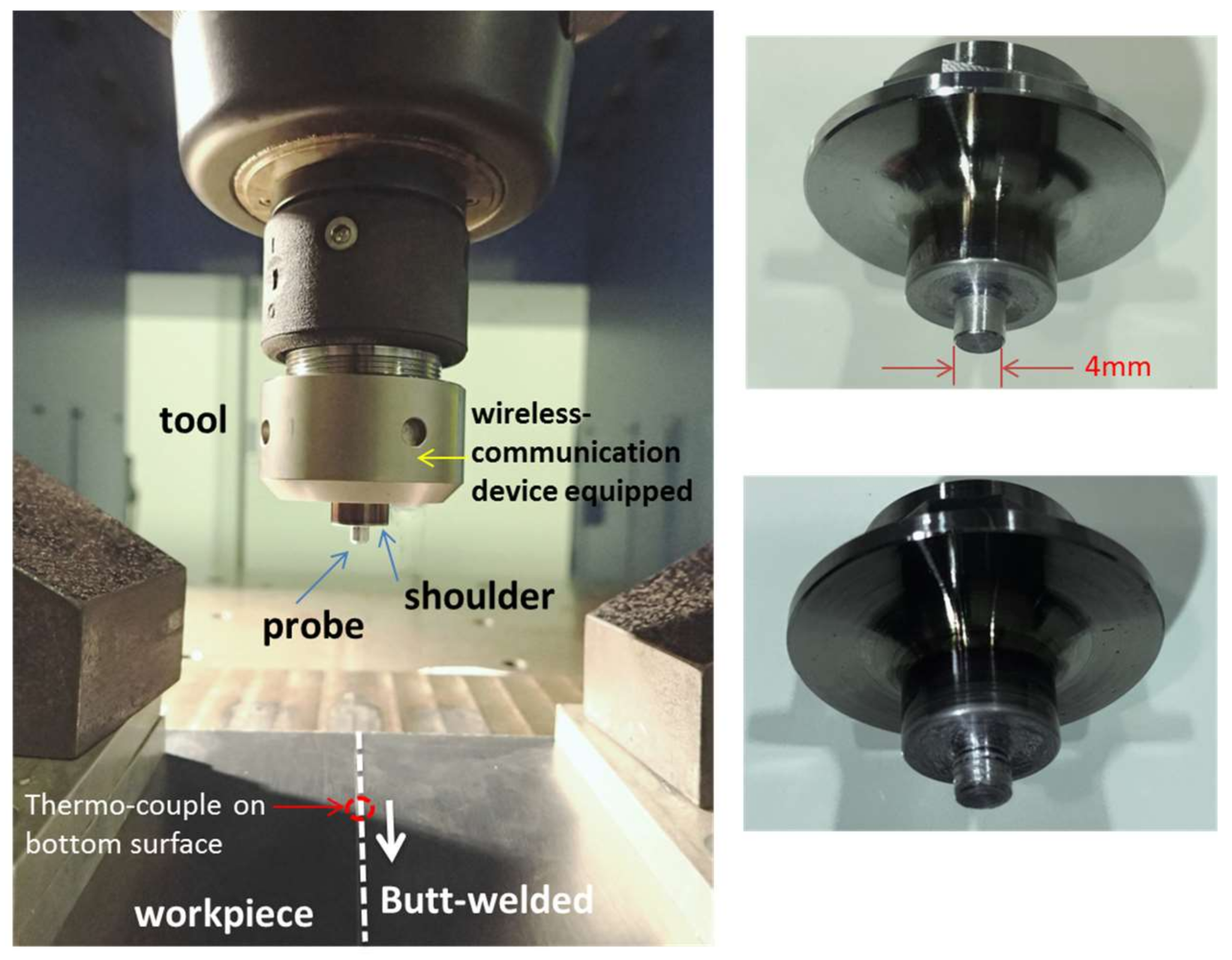

Contact of the pin with the workpiece creates frictional and deformational heating and softens the workpiece material.

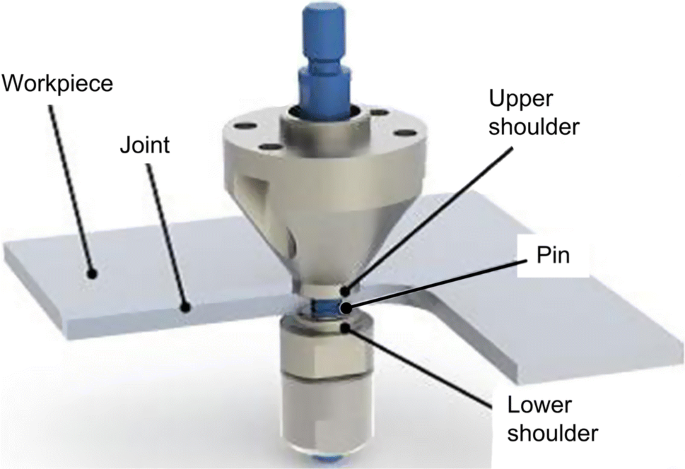

. Along the way several successful new tooling designs were developed for current issues at the. Contacting the shoulder to the workpiece increases the workpiece heating expands the zone of softened material and constrains the deformed material. The friction stirring tool consists of a pin or probe and shoulder.

Owing to the tool features the material flow around the tool probe can be extremely complex and significantly different from one tool to the other. The tool typically consists of a rotating round shoulder and a threaded cylindrical pin that heats the workpiece mostly by friction and moves the softened alloy around it to form the joint. Friction Stir Tooling Tool Materials And Designs.

Metal Cutting Theory and Friction Stir Welding Tool Design Author. Tool material and geometry 2. Tool Material Design for Friction Stir Welding of High Strength Materials.

Dynamic forces and material flow author Clark D E and Miller K S and Tolle C R abstractNote Friction stir processing involves severe plastic flow within the material. Different zone friction stir processed in materials such as aluminium alloys titanium alloys and steels. The tool materials include tool steels superalloys refractory metals carbides and ceramics and superabrasives.

Friction Stir Welding Tools - Functions Designs and Materials Published on November 14 2018 November 14 2018 11 Likes 0 Comments. Friction stir processing tool design microstructural characterization REFERENCES 1 W. Oelgoetz Auto-adjustable tool for friction stir welding US.

DebRoy1 Friction stir welding FSW is a widely used solid state joining process for soft materials such as aluminium alloys because it avoids many of the common problems of fusion welding. Friction Stir Welding FSW invented by TWI is a solid state welding technique in which the. This process is experimental and the keywords may be updated as the learning algorithm improves.

Material Flow Friction Stir Welding Tool Material Tool Shoulder Faying Surface These keywords were added by machine and not by the authors. A non - consumable rotating tool is employed of various designs which is manufactured from. The present chapter provides an overview of the most commonly-used friction stir tool designs and materials and welded joint configurations.

Process in such a way that the design of new tools for new materials could be accelerated. Friction stir processing is an emerging surfaceengineering technology based on the principles of Friction Stir Welding FSW. INTRODUCTION Friction stir welding FSW is a solid-state joining process that uses a non-consumable tool to join two facing work pieces without melting the work piece material.

Articleosti_912377 title Tool design in friction stir processing. Friction stir welding tools R. Fuller Rockwell Scientific Company.

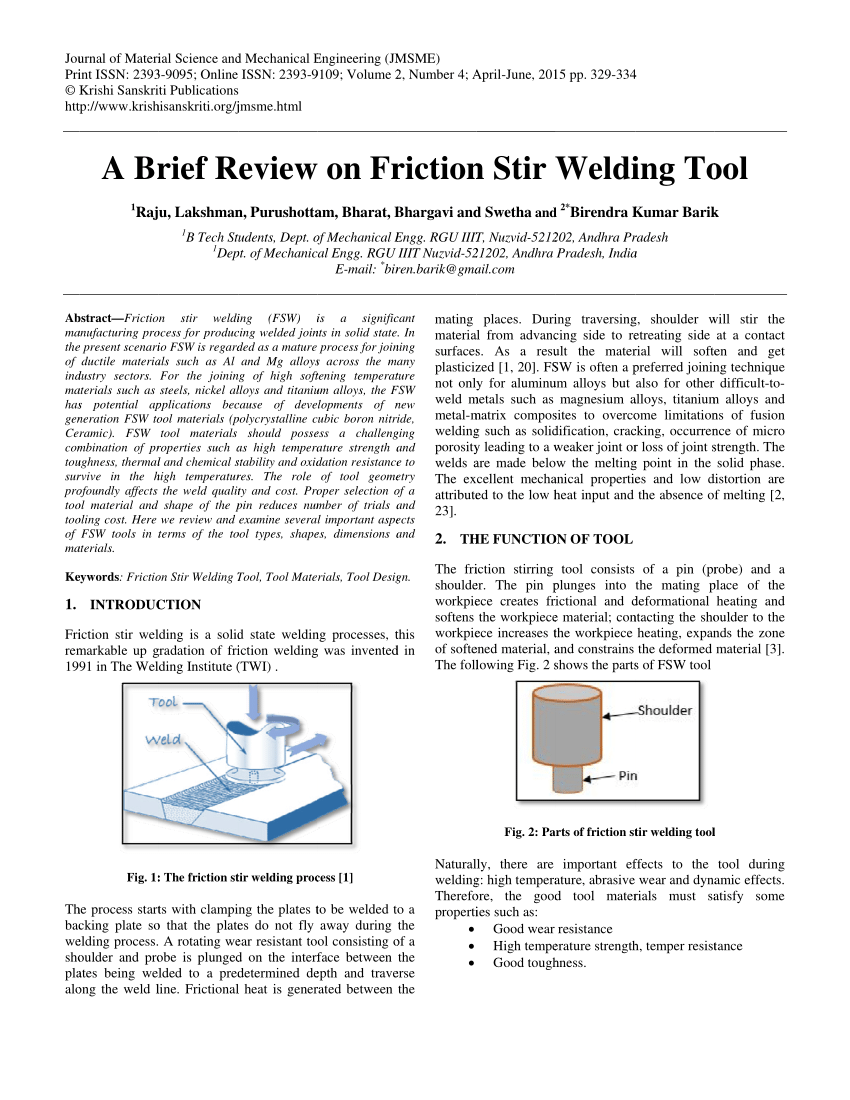

Fig 1 Schematic Illustration of friction stir welding. Thomas Development of improved tool designs for Friction Stir Welding of Aluminum First International Conference on Friction Stir Welding June 1999. Friction stir tooling tool materials and designs Mention a contemporary and vibrant design.

Friction stir processing tool design microstructural characterization fsp main parameter bulk material new solid state processing technique fsp fundamental material flow pattern different material local thermomechanical metal different zone friction stir tool rotational casting defect local property stainless steel tool design diversity fine-grained microstructures microstructural. Tool Materials and Designs. Friction stir welding is a relatively new joining process invented at The Welding Institute Cambridge UK in 1991 and developed initially for aluminum alloys.

Short tool life time and expensive tooling cost. Friction stir processing FSP is a new solid state processing technique that can locally eliminate casting defects and refine microstructures thereby improving strength and ductility increasing. A friction stir welding FSW 1 5 tool is obviously a critical component to the success of the process.

Chapter 2 Friction Stir Tooling. With The sunshine pinkish and white shades combined with the seemingly washed on peach colored petals demonstrates as When the sun has picked to glow on you and only you. Arbegast NSF Center for Friction Stir Processing CFSP Advanced Materials Processing and Joining Center AMP South Dakota School.

Frias Friction Stir Welding Tools and Developments Doc IIW-1639-03. This article discusses materials for friction stir welding FSW pin tools various tool geometries that have been used designs for specific applications predicting and measuring tool performance and other considerations in FSW pin tool design. The nature of this flow determines the final morphology of the weld the resulting microstructures and the presence or.

Therefore it is of great industrial interest to develop a new cost-effective tool material with the required high temperature strength and lasting tool life timenbspIn this SBIR program QuesTek Innovations LLC and. So there are two important aspects of friction stir welding tool design. Friction Stir Welding and Processing.

The primary goal of this SBIR Phase I project is to advance the development of low-cost functionally graded laser additive manufactured high temperature refractory and cermet pin tools for friction stir welding FSW andor friction stir processing FSP of heat-resistant materials. This nail art injects an exciting character in you. Most important Challenges of Friction Stir Welding are application of high temperature materials Tool material selection Development of Tool Materials Tool design and Complex geometries and dissimilar materials.

Tools For Friction Stir Welding

New Tool For Joining Ti 6al 4v By Friction Stir Welding Twi

Friction Stir Spot Welding Tool Design Showing Geometric Parameters Download Scientific Diagram

Pdf A Brief Review On Friction Stir Welding Tool

A Schematic Of The Friction Stir Welding Technique Download Scientific Diagram

Tools For Friction Stir Welding

Research Progress Of Bobbin Tool Friction Stir Welding Of Aluminum Alloys A Review Springerlink

Metals Free Full Text Friction Stir Welding Of Non Heat Treatable High Strength Alloy 5083 O Html

0 comments

Post a Comment